PRODUCTION OF MECHANICAL PARTS, PROTOTYPES AND SMALL SERIES

HIGH TECHNOLOGY AND VARIOUS APPLICATIONS

Thanks to a complete and regularly renewed machine park, Novoutils produces, per unit and in small series, mechanical parts designed for various applications and users:

- Metrology: ring gauges, gauges made in carbide, taper plugs

- Mechanical parts for custom machines, adjustement subassembly

- Clamp devices: collet, jaw, spindle, holders on demand.

- Tools: supporting rollers.

Machined material:

- Steel, stainless steel, special steels

- Alloys steel, non ferrous alloys

- Aluminium

- Coper, brass

- Plastics material

- Titanium

STUDY, DESIGN, CONCEPTION, TRACEABILITY

Our study department

- 2D software – Design Cad

- Software TOP Solid 7.14

- CAM Goelan EDM machines

Our study department, according to your drawings, design mechanical parts (prototypes and series)

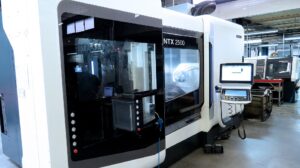

A complete machinery for the control of deadlines

Sliding head lathes and fixed headstock lathes

Sliding head lathes and fixed headstock lathes

2 mill turn lathes

3 machining centres

1 CNC lathe – dual spindle- a tool clamping part

Milling: Conventional and CNC (4 axes or 5 continuous axes)

- From 10 x 10 x 10 to 950 x 600 x 350

Turning: Conventional and CNC

- From Ø 3 Lenght 10 to Ø 250 Lenght 400

EDM machines: wire electrical discharge machining , electrical discharge sinking

- From 318 x 218 x H=145 to 600 x 400 x H=280

Grinding: plane grinding, cylindrical grinding (external and internal) and grinding of complexe profiles.

Sizes:

- Plane grinding : 1 x 1→ 150 x 300 ; +/- 5µm

- External cylindrical grinding : Ø 0.1 x lg 0.15 → Ø 200 x lg 350 ; +/- 5µm

- Internal cylindrical grinding : Ø 0.1 x lg 0.15 → Ø 200 x lg 350 ; +/- 5µm

- Grinding of complexe profiles : Ø 7 x lg 1 → Ø 200 x lg 100 ; +/- 5 µm

Cutting,polishing, honing, brazing

Laser marking: We engrave on your parts a number which guarantees traceability and quick problem solving.

METROLOGY

- ISO 9001/2015

- Traditional equipment of measure

- Profile projectors with lenses 20, 50 and 100

- Three-dimensional measuring machines ZEISS (CONTURA)

- Measuring bench with 2 cameras et 3D sensor GALLILEO

- Control device with camera – Marcel Aubert